-

-

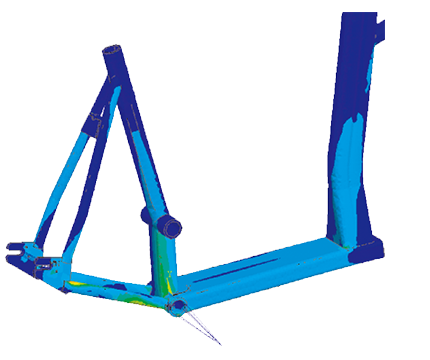

Numerical simulation of the deformations in all conditions improvement in frame tension conditions upon performing.

-

- ANSYS 5.4

- DEC 25 2003

- 19:40:50

- NODAL SOLUTION

- STEP = 1

- SUB = 1

- TIME = 1

- EPTOEQV (AVG)

- EffNu = 0

- PowerGraphics

- EFACET = 1

- AVRES = MAT

- DMX = .723216

- SMX = .471E - 03

- .523R - 04

- .105E - 03

- .157E - 03

- .209E - 03

- .261E - 03

- .314E - 03

- .366E - 03

- .418E - 03

- .471E - 03

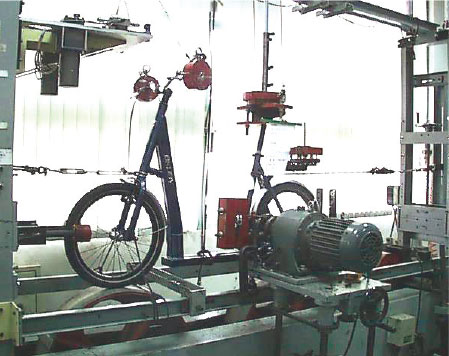

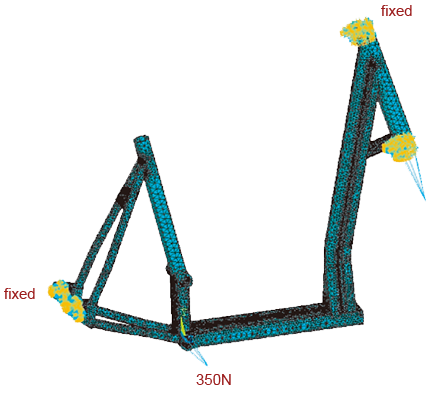

Testing with the standard action force 350N acted on the bottom bracket, and the frame is fixed.

The distribution plot of the righdity strain of twist on the bottom bracket:

- Displaying the distribution range of resistance strength against the twist rigidity strain on the bottom bracket.

- The strain values illustrate the possibility of deformation of the frame caused by an extern twist force 350Non the bottom bracket, and to be displayed with distinguished color. The max strain value is on the chain stay.

- It indicates the max strain value is still within the safety standard.

-

NANO TECH in bicycles

PVDF(PVF2) coating which is widely applied on aero shuttle and building construction but now it is additional choice for our bikes as it is with excellent corrosion resistance, excellent heat resistance, chemical, and stain resistance. Through various tests, it appears with better effects than that of polyester, siliconized polyester, acrylic or PVC drgano-sol.

In ETW, to make bikes better than others is always in our minds so that, in addition to PVF2 coating, you can here see the NANOMETERS (PVDA) coating already applied in our bikes. It performs much better than all current coatings in every category such as liquid, powder and acrylic coating. Look this SKUBY frame with unsurpassed thermal, chemical and ultra violet resistance. Better color retention, better gloss retention, and better resistance to chalking so that you can enjoy the original taste of the bike you own, hex-chromium free and shining.

-

LABORATORY TEST & TECHNICAL DATA

Precision, hand built, first class technology, reliability and maintenance free are the proof of the extraordinary performance principal.

Reaching limits whilst maintaining the highest possible quality is the measure of all things at SKUBY’s bike. In this way we travel a unique path with our development partner. Individual components are constructed to work perfectly with each other from the outset. The result is a unique, exclusive frame geometry, which achieves maximum rigidity and an exceptional “Stiffness to Weight” ratio using the most intelligent, minimal amount of material.

SKUBY has passed and approval by DIN 79100 and JIS D9301 2004.